In a lot of thermal processes arising waste heat can’t be recovered for immediate reuse but few moments later, process heat on the same or a lower temperature level could be used. A typical example occurs in the ceramic industry. Heat from the kiln is used for clay drying but many times there is a time gap between these two processes.

A process can need a constant thermal input while the power level of an adapted waste heat stream is fluctuating above and below that level or is even often interrupted.

A typical example where huge high temperature thermal storage is used are Concentrating Solar Power stations (CSP) to get them producing electricity also at night.

By storing coldness it could be avoided to cause short but high power demands to the grid by cooling machines when high cooling loads are applied, for instance by filling a cold store with fresh products.

In HVAC as well as in cold stores, it can also be applied to shift electricity consumption to lower price periods.

During the seminar, you will learn about the status for industrial use by means of research results, outcome of case studies and references brought by some manufacturers. A lab scale demo can be visited and will be explained and demonstrated. It concerns a 150 kWh PCM based storage with melting temperature of 222°C. Also a software tool to design thermal processes including thermal storage will be demonstrated.

This seminar is also meant as a final dissemination activity within the frame of the CORNET-project “Short term heat or cold storage in industry (Shortstore)”

Project partners:

Research frame: CORNET with project partners in Belgium (Flanders) and Germany, also funded by the Flemish (VLAIO) and German (AiF) governments.

To allow the increase of share of renewable electricity generation, more flexibility on the demand side is required.

One of the possibilities is to convert electricity into heat for direct use or to store during over supply of (renewable) electricity. During shortage, electricity could be generated out of the stored heat again. The round trip efficiency is an important quality parameter.

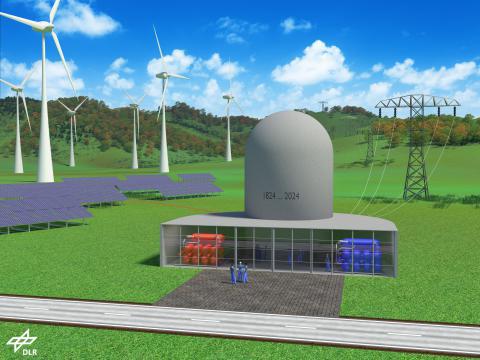

Together with CORNET partner DLR, UGent is involved in the H2020 project called “CHESTER”, meaning “Compressed Heat Energy Storage for Energy from Renewable sources”, currently running (01/04/2018 to 31/03/2022).

The concept contains two heat storage buffers at different temperatures. The lower one (stratified 40-90°C) can be fed by waste heat, thermal solar panels, geothermal heat (if present) etc… When excess renewable electricity is available, a heat pump will be applied to upgrade heat (80-90°C) to the temperature level of the high temperature storage (130-180°C). When shortage occurs, electricity will be generated out of the high temperature storage by means of an ORC (Organic Rankine Cycle). Because of a lower condenser temperature (~40°C) compared to the heat source temperature of the heat pump, part of the cycle losses could be covered.

During the conference first results will be presented.

For the transformation of the European electricity grid from fossil fuels to renewable energy sources, the harvesting of flexibilities on the consumer side is an essential part. Unfortunately many industrial consumers, especially SMEs, seldom participate in flexible electricity markets or capacity market. In many cases this is due to the fact, that it is very time consuming and expensive to decide in what way they could benefit from the participation in flexibility markets or what other kinds of business models would make sense for their certain situation.

Via a new CORNET project proposal the project team is aiming to develop methods that enable companies to take decisions towards more flexible energy systems and evaluate the technical, economic, ecological and organizational consequences. The implications of operating a flexible energy system and the benefits from the flexibility are in most cases not easily overseen. Technical restrictions of the devices in the energy systems are often not known, because they didn’t have to operate in a flexible way in the past. Legal implications are manifold in European countries due to a very high number of energy laws. Organizational implications are also hard to oversee and those are in many cases the main reason for companies not to operate their energy systems more flexible and join certain flexibility markets with their devices.

The project will be especially directed to companies having own electricity production facilities such as CHP (Combined Heat and Power) but also renewables like a wind turbine or PV-panels. But also direct heat generation and storage with electricity, bot for high temperatures (steam) or lower temperatures (hot water) could be part of a technical solution.

By integrating Thermal Energy Storage (TES), a CHP will become much more flexible also meet the requirements for optimal operation in the current energy markets. Even existing CHPs could be adapted this way.

For storage temperatures below 100°C water buffer tanks are a proven solution. No technological research is needed for that. But as this solution is often used on the smaller engine based CHPs, a lot of exploiters are still buying electricity against fixed contract prices.

Above 100°C mostly steam producing gas turbine based CHPs are chosen. Here TES is still very rare despite adapted solutions are existing and in use in for example Concentrating Solar Power (CSP) installations to allow them producing electricity at night or during cloudy periods. The two-tank molten salt system is common state of the art for the bigger CSPs, up to 100 MWe and more. For smaller installations, research is ongoing to other technologies such as concrete, Phase Changing Materials (PCMs), rocks etc. as a storage material or even storage via reversible thermo chemical reactions.

Combined electrical-gas fired steam boilers are appearing as well. When electricity prices are low steam is generated with electricity.

If applied, all of the proposed solutions should increase generated revenues for industrial energy consumers but also increase the flexibility of the energy market needed to increase the share of renewable energy generation.

A new CORNET project proposal, named “Increase flexibility of your cogeneration unit by adding thermal storage” is in preparation to formulate an answer on following questions:

- How can CHP operators better make use of variable electricity prices?

- Can the latter be optimized by adding thermal storage?

- What kind of thermal storage systems are well adapted and available for CHPs?

Beneficiaries of the project results are exploiters of both small and bigger CHPs, present in very different industrial branches, CHP manufacturers and installers, engineering offices, grid operators and energy contractors. All of them will be represented in the user groups.

During the conference state of the art will be introduced. Also you will learn about the organization of the electricity market and about some existing references of electricity generation units with integrated thermal storage.